Why Pull Studs Matter More Than Most Shops Think

Zero-point workholding is often discussed in terms of base chucks, pallets, and vises—but the truth is simpler: the system is only as repeatable as the interface that connects the “fixture world” to the “base world.” In many setups, that interface is the pull stud.

Pull studs take the load path seriously. They help define how consistently a fixture is pulled into location, how stable it remains under cutting forces, and how much vibration gets transmitted (or resisted) during machining. When pull studs are treated like generic hardware, shops often experience “mystery” issues: inconsistent surface finish, slight shifts after swapping plates, and repeat jobs that need re-indicating even though they shouldn’t.

What Good Pull Studs Are Designed to Do

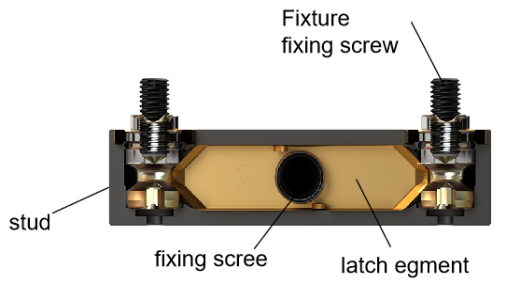

A clear example is Xindian’s 52mm Fixture Pull Stud set, described as precision-engineered for secure, precise workholding. The product highlights hardened steel construction for durability and wear resistance, along with consistent clamping force intended to minimize vibration and improve machining accuracy and surface finish.

That “consistent clamping force” line is not fluff. Under load, small variations at the interface can become micro-movement. Micro-movement becomes chatter. Chatter becomes tool wear and unpredictable finish. If you’re building a repeatable quick-change workflow, pull studs aren’t accessories—they’re functional accuracy components.

52mm vs 96mm Pull Studs: Choose the Workflow First

Many shops ask which size is “better,” but the more useful question is: which size matches your fixture ecosystem?

52mm pull studs are positioned as widely compatible and easy to install, with the same focus on hardened steel and stable clamping. They’re often a natural fit for compact tooling plates, smaller fixtures, and high-mix work where lighter plates are easy to handle.

96mm pull studs follow the same design intent—hydraulic vise , easy installation, and consistent clamping force that helps minimize vibration and improve accuracy/finish. They’re also described as compatible with a wide range of CNC chucks, which typically aligns with larger fixture footprints or heavier-duty plate strategies.

Practical guidance:

- If most of your work fits smaller vises and plates, standardize on 52mm first.

- If you frequently use larger vises/chucks/plates—or handle heavier workpieces—96mm may better match your “platform” size.

The real ROI comes from standardization. Mixed ecosystems can work, but only if they’re clearly labeled and operationally disciplined.

Don’t Ignore Material and Heat Treatment (Especially in Coolant-Heavy Shops)

Pull studs live a hard life: repeated clamp/unclamp cycles, exposure to coolant, chip contamination, and occasional operator abuse. Material choice changes how studs age over time.

For example, Xindian’s pneumatic chuck pull stud for 3R SYSTEM integration is described as martensitic stainless steel, vacuum heat-treated to HRC55, with listed dimensions 20mm × 20mm × 57mm, and designed to facilitate secure connection/locking between base chucks and pull studs.

That combination tells you what it’s optimized for: durability in demanding environments and stable functional performance across repeated cycles.

Installation Discipline: The #1 Reason “Repeatability” Fails in Real Life

Both the 52mm and 96mm pull stud products emphasize easy installation. But “easy” doesn’t mean “careless.” Most repeatability problems are caused by inconsistent practices:

- Inconsistent torque or seating across studs on different plates

- Dirty interfaces (chips/coolant residue) that prevent full seating

- Mixed batches of studs treated as interchangeable even when worn differently

- Damaged threads that still “feel okay” but don’t clamp consistently

If you want your quick-change system to behave like a system, treat pull studs like controlled tooling: standard torque practice, clean handling, and proactive replacement when worn or damaged.

A Simple Pull Stud Checklist (Fast, Practical, Repeatable)

Use this quick checklist before scaling a fixture library:

- Standardize one size per machine group (52mm or 96mm) to reduce confusion.

- Define one installation method (same tools, same torque approach, same cleaning routine).

- Label plates clearly so operators don’t guess.

- Inspect periodically for wear, dings, and contamination.

- If using 3R integration, match the pull stud spec designed for that ecosystem (material and HRC details matter).

Bottom Line

Pull studs are small, but they sit at the most critical interface of a zero-point workflow. The 52mm and 96mm pull studs are described with hardened steel durability and consistent clamping force aimed at reducing vibration and improving 5th axis vise , while a 3R-oriented pneumatic pull stud is specified with martensitic stainless steel and HRC55 heat treatment for demanding environments.